Fortu Tech specializes in the production of alloy materials for 4D printing. 4D printing technology refers to the structure printed by 3D technology can change shape or structure under external incentives. It directly builds the deformation design of materials and structures into the material, thus simplifying the process from design concept to physical creation. This allows objects to be assembled automatically, enabling the integration of product design, manufacturing and assembly.

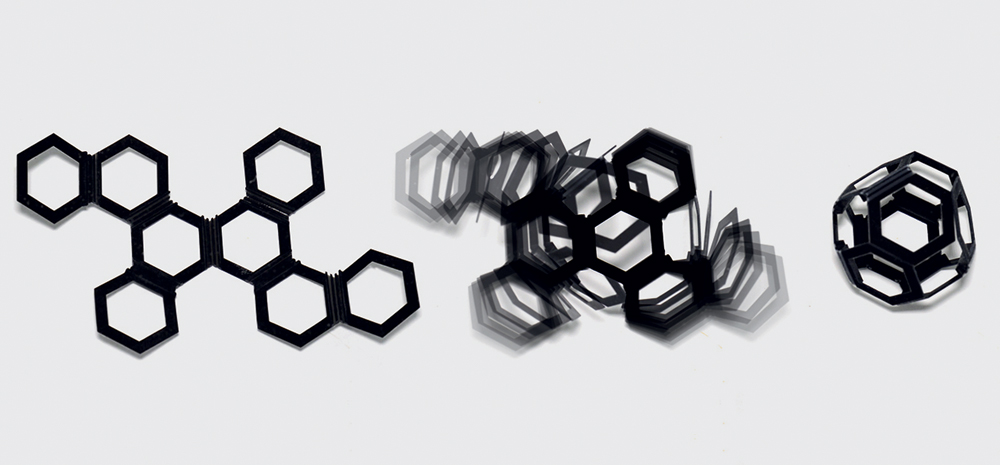

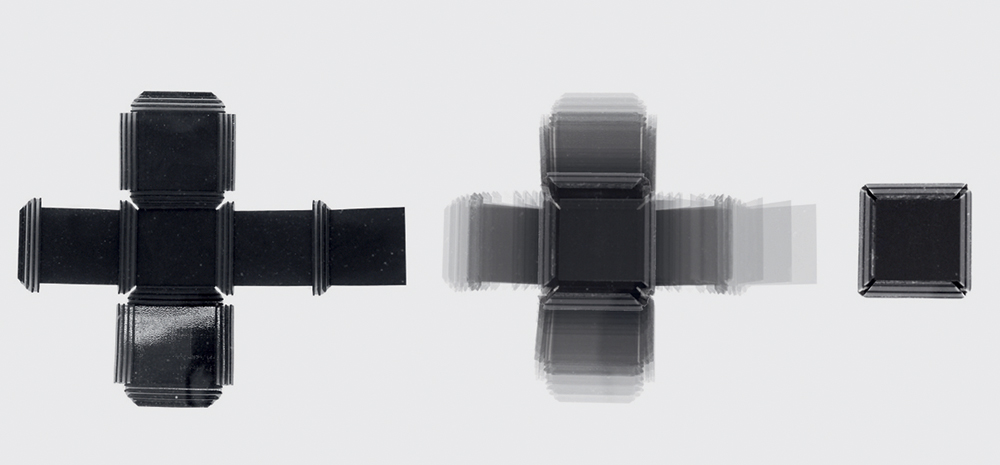

4D printing produces objects in at least two forms: one is that the parts of the object are joined together and can transform themselves into another form or property. The other is that the object consists of detachable three-dimensional pixels that can be aggregated to form larger programmable parts that can also be decomposed into three-dimensional pixels.

Because of the time-dependent nature of 4D printing structures, there are one or more intermediate forms in the design and production process.

The middleware molding process requires the work of a new 3D printing facility. The 4D printing process requires the support of appropriate mathematical models. After the digital design is completed, the data is transmitted to the printing equipment for analysis, so that the material can be reasonably arranged to ensure the final printing effect.

It can be predicted that the future 4D printing equipment will develop in the direction of standardization and modularization.

The replaceable ability of different modules can basically guarantee the support for different materials and different platforms.

If you have inquiry or want to discuss your design with us, please write email to us.

We will reply your email within 24 hours.

Traditional 3D printing techniques can obtain 3D data of objects through professional scanners or DIY scanning equipment, or 3D digital models can be built from scratch using 3D production software.

Different from 3D printing modeling, 4D printing pre-implanting deformation factors such as triggering medium, time and other relevant digital parameters into printing materials at the beginning of digital modeling due to its changeable characteristics.

4D printing is unique in that it has one more "D", or temporal latitude, than 3D printing. 4D printing allows materials to change shape or function over time as external conditions change, in addition to moving around the X, Y and Z axes.

4D printing materials can be self-reconfigured to change color, shape and performance. The existing 4D printing technology is mainly limited to organic materials, but organic materials have poor high temperature resistance.

As a 4D printing material, niobium-titanium alloy has better high temperature and corrosion resistance than organic materials. At the same time, in the process of preparing 4D printing materials for niobium titanium alloy, screening niobium titanium alloy wire to niobium titanium alloy powder can improve the efficiency of 4D printing materials preparation.

Add: 399 Chunhe Road, Baoshan District, Shanghai, China, 200941

Tel: +86 21 56656030

Email: info@fortu-tech.com