Powder Metallurgy

Powder metallurgy is the use of metal powder as raw material. After forming and sintering the metal powder is made into metal material.

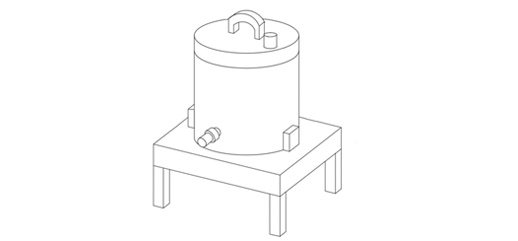

Vacuum vertical melting sintering is one of the main methods to prepare refractory metals such as tantalum, niobium, tungsten and molybdenum by powder metallurgy. In the process of high temperature vertical melting, the workpiece needs to be suspended, so that the workpiece is not subject to any tension and pressure from the outside to ensure the quality of the product vertical melting.

Process of powder metallurgy

(1) Powder production. The production process of powder includes powder preparation, powder mixing and other steps.

(2) Pressing molding. The powder is pressed into the desired shape under certain pressure.

(3) Sintering. Sintering is carried out in high temperature furnace or vacuum furnace with protective atmosphere. Sintering is different from metal melting. At least one element remains solid during sintering.

Through a series of physical and chemical processes such as diffusion, recrystallization, fusion welding, combination and dissolution, powder particles become metallurgical products with certain porosity in the sintering process.

(4) Post-processing. Under normal circumstances, sintered parts can be used directly. But for some size requirements of high precision and high hardness, wear resistance of the parts should be sintered after processing.

Post-treatment includes fine pressing, rolling, extrusion, quenching, surface quenching, oil immersion, and melting, etc.

| The tensile strength of niobium sheet | ||||

| Production Method | Status | Tensile Strength | Elongation | Bending Angle |

| Powder metallurgy | Before annealed | 63 kg/mm3 | 8.7 | <130 |

| 1100 ℃, 1 hour | 35 kg/mm3 | 37.5 | <130 | |

| The tensile strength of tantalum sheet | ||||

| Production Method | Status | Tensile Strength | Elongation | Bending Angle |

| Powder metallurgy | Before annealed | 87 | 7.5 | >140 |

| 1100 ℃, 1 hour | 40.3 | 42.5 | >140 | |

| Titanium alloy powder metallurgy | ||||

| Materials | O | Tensile Strength | Yield Strength | Elongation |

| Grade1 | ≤1800ppm | ≥520MPa | ≥400MPa | ≥20% |

| Ti-6Al-4V | ≤1800ppm | ≥1000MPa | ≥900MPa | ≥12% |

GET IN TOUCH WITH US

CONTACT US

Add: 399 Chunhe Road, Baoshan District, Shanghai, China, 200941

Tel: +86 21 56656030

Email: info@fortu-tech.com