Fortu Tech specializes in manufacturing Nb1Zr, Niobium alloy containing 1 % zirconium products.

| Nb1Zr/ Niobium alloy containing 1 % zirconium | ||

| Nb1Zr Foil | Nb1Zr Wire | Nb1Zr Sheet |

| Nb1Zr Rod | Nb1Zr Targets | Nb1Zr Tube |

| Nb1Zr Pellet | Nb1Zr Fasteners | Nb1Zr Ingot |

| Niobium alloy containing 1 % zirconium | |||

| Shape | Standard | Type | Grade |

| Nb1Zr Ingot | ASTM B 391 | R04251-Type 3 | Reactor grade |

| Nb1Zr Ingot | ASTM B 391 | R04261-Type 4 | Commercial grade |

| Nb1Zr Bar/Rod/Wire | ASTM B 392 | R04251-Type 3 | Reactor grade |

| Nb1Zr Bar/Rod/Wire | ASTM B 392 | R04261-Type 4 | Commercial grade |

| Nb1Zr Sheet/Strip/Plate | ASTM B 393 | R04251-Type 3 | Reactor grade |

| Nb1Zr Sheet/Strip/Plate | ASTM B 393 | R04261-Type 4 | Commercial grade |

| Nb1Zr Tube | ASTM B 394 | R04251-Type 3 | Reactor grade |

| Nb1Zr Tube | ASTM B 394 | R04261-Type 4 | Commercial grade |

Because of its good performance, Nb-1Zr alloy is the most widely used niobium alloy. It is a low-strength niobium alloy with good processing and welding performance.

Niobium alloy containing 1 % zirconium has the performance of small capture section of hot seeds as well as strong resistance to liquid metal corrosion.

| ASTM Standard Chemical Requirements Nb1Zr/ Niobium alloy containing 1 % zirconium | |||||||||||||||||||

| Element % | C | N | O | H | Zr | Ta | Fe | Si | W | Ni | Mo | Hf | Ti | B | Al | Be | Cr | Co | |

| Reactor Grade | Type 3 | 0.01 | 0.01 | 0.015 | 0.0015 | 0.8-1.2 | 0.1 | 0.005 | 0.005 | 0.03 | 0.005 | 0.01 | 0.02 | 0.02 | 2 ppm | 0.002 | 0.005 | 0.002 | 0.002 |

| Commercial Grade | Type 4 | 0.01 | 0.01 | 0.025 | 0.0015 | 0.8-1.2 | 0.5 | 0.01 | 0.005 | 0.05 | 0.005 | 0.05 | 0.02 | 0.03 | / | 0.005 | / | / | / |

If you have inquiry or want to discuss your design with us, please write email to us.

We will reply your email within 24 hours.

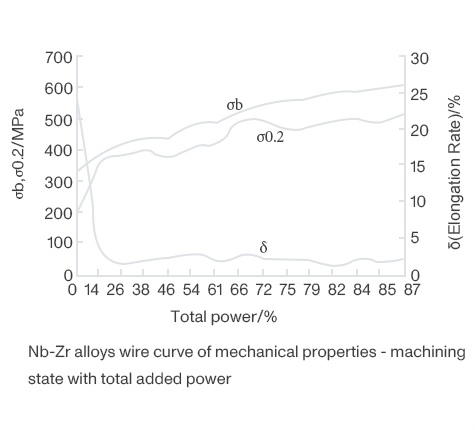

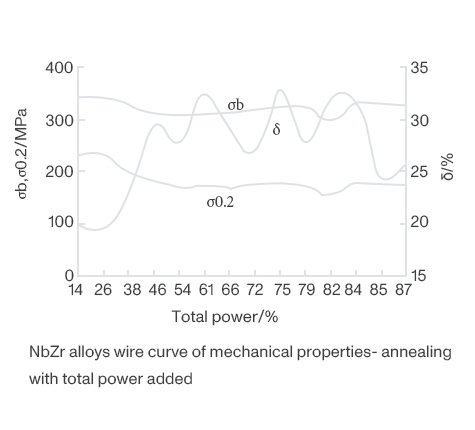

| Mechanical Property Nb1Zr/ Niobium alloy containing 1 % zirconium | ||

| σb | δ | Temperature |

| 320~420 MPa | 20%~40% | Room Temperature |

According to the requirements of performance and purity of gap impurities (carbon, oxygen and nitrogen), the ingot of Nb-1Zr alloy can be prepared and manufactured by consumable arc furnace and electron beam furnace.

If purity requirements of Nb1Zr Ingot is low, it can also be formed and sintered by mixing niobium powder and zirconium powder.

It is mainly used in lighting industry and aerospace industry to produce atomic reactor, electric source sodium lamp, turbopumps of space nuclear power generation equipment and liquid alkali metal conveying pipeline.

And Nb-1Zr alloy also can be used in manufacturing the thrust chamber body extension of spacecraft, satellite, missile attitude control and maneuver engine.

Add: 399 Chunhe Road, Baoshan District, Shanghai, China, 200941

Tel: +86 21 56656030

Email: info@fortu-tech.com