Fortu Tech specializes in manufacturing NbTi Alloys (Nb-10Ti alloys, Nb-47Ti alloys, Nb-50Ti alloys and Nb-55Ti alloys)

| 53Nb47Ti alloys Regular Product ASTM B884 | ||

| 53Nb47Ti Foil | 53Nb47Ti Wire | 53Nb47Ti Sheet |

| 53Nb47Ti Rod | 53Nb47Ti Targets | 53Nb47Ti Tube |

| 53Nb47Ti Pellet | 53Nb47Ti Fasteners | 53Nb47Ti Ingot |

| Nb45Ti55 alloys Regular Product | ||

| Nb45Ti55 Foil | Nb45Ti55 Wire | Nb45Ti55 Sheet |

| Nb45Ti55 Rod | Nb45Ti55 Targets | Nb45Ti55 Tube |

| Nb45Ti55 Pellet | Nb45Ti55 Fasteners | Nb45Ti55 Ingot |

| Nb90Ti10 alloys Regular Product | ||

| Nb90Ti10 Foil | Nb90Ti10 Wire | Nb90Ti10 Sheet |

| Nb90Ti10 Rod | Nb90Ti10 Targets | Nb90Ti10 Tube |

| Nb90Ti10 Pellet | Nb90Ti10 Fasteners | Nb90Ti10 Ingot |

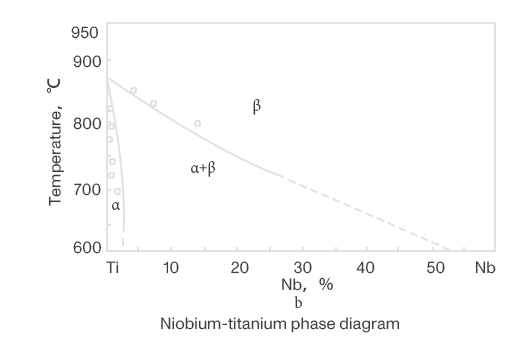

The niobium titanium alloy with niobium content of 40 ~ 60wt % has the following characteristics: high specific strength, non-magnetism, high thermal resistance, excellent superconductivity, excellent mechanical stability and good biocompatibility.

In annealed state, NbTi alloy shows good mechanical properties, machining properties and corrosion resistance. So, it is an ideal material for manufacturing aerospace fasteners and superconductors.

| Nb50Ti50 alloys Regular Product | ||

| Nb50Ti50 Foil | Nb50Ti50 Wire | Nb50Ti50 Sheet |

| Nb50Ti50 Rod | Nb50Ti50 Targets | Nb50Ti50 Tube |

| Nb50Ti50 Pellet | Nb50Ti50 Fasteners | Nb50Ti50 Ingot |

| ASTM B884 53Nb-47Ti | ||||||||||||

| Element | Al | C | Cr | Cu | H | Fe | Ni | N | O | Si | Ta | Ti |

| Content Maximum % | 0.01 | 0.02 | 0.01 | 0.01 | 0.0045 | 0.02 | 0.01 | 0.015 | 0.1 | 0.01 | 0.25 | 46% to 48% |

| Grade 36 45Nb-55Ti | ||||||

| Element | N | C | H | Fe | O | Nb |

| Content Maximum % | 0.03 | 0.04 | 0.0035 | 0.03 | 0.16 | 42% to 47% |

If you have inquiry or want to discuss your design with us, please write email to us.

We will reply your email within 24 hours.

First, titanium sponge is pressed into titanium electrode, then the consumable electrode is made from titanium electrode block and niobium rod, and then, smelting the alloys several times, finally the NbTi alloys Ingot is finished.

Note:

Fill the furnace in the vacuum consumable electric arc furnace and pump out the furnace, check the inlet temperature.

When the inlet temperature is less than 20℃, set the inlet temperature to 20℃ and the outlet temperature to 30℃.

When the inlet temperature is greater than 20℃, the inlet temperature is set as the measured temperature, and the outlet temperature is set as 30℃.

Niobium-titanium alloys is a kind of superconducting alloy. NbTi alloys are usually used in superconducting magnets and wires, in particle colliders, aerospace components and other applications. When using 50%Nb50%Ti wire, it is usually necessary to use copper to wrap it.

Niobium-titanium alloys are also used to make components in MRI scanners. Because of their density and good mechanical properties, light fasteners for aircraft can also be made by Nb-45% Ti alloy. Nb-55Ti alloy can be used not only in anti-corrosion engineering components but also in high pressure equipment.

In industrial use, niobium titanium alloys are used as superconductor wires for superconducting magnets. Now niobium-titanium alloys are also beginning to be used in surgical implants.

Add: 399 Chunhe Road, Baoshan District, Shanghai, China, 200941

Tel: +86 21 56656030

Email: info@fortu-tech.com