Fortu Tech specializes in manufacturing Nb10Zr, Niobium alloy containing 10% zirconium products.

| Nb10Zr/Niobium alloy containing 10 % zirconium | ||

| Nb10Zr Foil | Nb10Zr Wire | Nb10Zr Sheet |

| Nb10Zr Rod | Nb10Zr Targets | Nb10Zr Tube |

| Nb10Zr Pellet | Nb10Zr Fasteners | Nb10Zr Ingot |

A Nb-Zr 90/10 wt% alloy can be produced by adding a certain proportion of zirconium to niobium. After adding zirconium, the strength of niobium zirconium alloy can be improved without affecting the plasticity and machining properties of Nb-Zr 90/10 wt% alloy.

In addition, zirconium can also improve the oxidation resistance and alkali metal corrosion performance of niobium zirconium alloy 10, improve the processing and weldability of niobium zirconium alloy.

At the same time, a small amount of element C is added to form carbide for aging strengthening.

When necessary, the form and distribution of precipitated phase carbide can be controlled by proper processing and heat treatment, so as to improve the strength of Nb10%Zr alloy and greatly improve the creep resistance of Nb10%Zr alloy at high temperature.

| Chemical Requirements Nb-10%Zr alloys | ||||||

| Element | C | N | O | H | Ta | Zr |

| Content Maximum % | 0.01 | 0.008 | 0.04 | 0.002 | 0.08 | 9~11 |

If you have inquiry or want to discuss your design with us, please write email to us.

We will reply your email within 24 hours.

Nb ingot was prepared

Nb ingot was made by secondary electron bombardment furnace smelting with niobium strips conforming to the standard.

The Nb ingot was made into Nb ingot after the head was removed and the tail was flattened by lathe.

Preparation of zirconium slats

Zirconium ingots are prepared by the method of secondary melting in vacuum electric furnace consumable furnace, and zirconium slats are rolled by lathe after the head is removed and the tail is flat.

The composition of zirconium slats meets the standards.

The length of zirconium slats shall be consistent with that of the prepared niobium ingot.

Electrode preparation

The prepared niobium ingot and the prepared zirconium strip according to a certain proportion to make zirconium niobium vacuum consumable electrode, wherein the prepared zirconium niobium vacuum consumable electrode, zirconium ingot and niobium ingot strip mass ratio is 1:9.

Vacuum consumable electric arc furnace smelting.

Secondary melting in vacuum consumable electric arc furnace

The primary niobium alloy containing 10 % zirconium ingot was skinned until the surface was bright and no defects were visible to the naked eye. The secondary Niobium10%zirconium ingot was made after secondary melting under appropriate technical parameters.

The Nb10Zr alloys ingot is skinned until the surface is bright without visible defects, and then the finished NbZr10 alloy ingot is prepared after the sampling analysis is qualified.

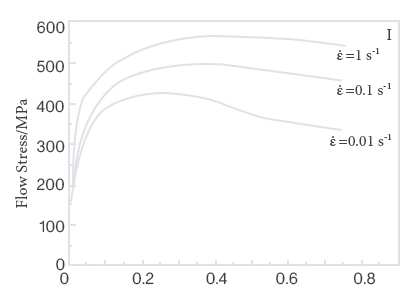

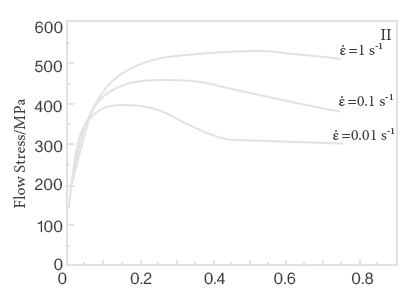

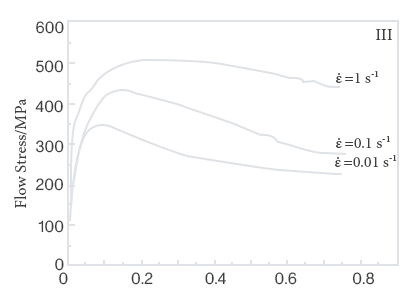

Nb10Zr alloys show dynamic recovery and dynamic recrystallization softening characteristics with increasing temperature and decreasing strain rate from 1273 to 1373 K and 0.01~1 s-1.

The activation energy of Nb10Zr alloy at high temperature varies greatly with the flow stress, and the peak value is 436.17 kJ/mol where the flow stress changes the most.

Nb-10%Zr alloys are often produced as Nb-10%Zr targets and Nb-10%Zr rotating targets.

Niobium 10% Zirconium alloys are widely used in Vacuum sputtered building glass, solar, photovoltaic coating, aerospace, aviation industry and other applications.

The NbZr10 alloy target/plate used in building glass, photovoltaic and other fields is rectangular plate shape, the length is generally 3 to 4 meters.

Add: 399 Chunhe Road, Baoshan District, Shanghai, China, 200941

Tel: +86 21 56656030

Email: info@fortu-tech.com