Superconductivity is the property of certain substances that reduce their electrical resistance to zero under certain conditions of temperature (generally low temperatures).

Superconducting materials and superconducting technology have broad application prospects.

Superconducting elements: There are 28 elements with superconductivity at atmospheric pressure, among which Niobium (Nb) has the highest Tc of 9.26K.

Niobium and lead (Pb, Tc=7.201K) are the main practical applications in electrical engineering, which have been used in the manufacture of superconducting AC power cables, high-Q resonators, etc.

Superconducting compounds: Superconducting elements often have excellent superconducting properties when combined with other elements. For Nb3Sn, which has been widely used, its Tc=18.1K and Hc=24.5. Other important superconducting compounds are V3Ga, Tc=16.8K, Hc=24; Nb3Al, Tc=18.8K, Hc=30.

Superconducting ceramics.

Alloy materials: superconducting elements adding some other elements as alloy components can improve the overall performance of superconducting materials.For example, the first Niobium zirconium alloy (Nb-75Zr) has a Tc of 10.8K and Hc of 8.7. This was followed by niobium titanium alloys, where although the Tc is slightly lower, the Hc is much higher and can carry more current in a given magnetic field. Its performance is Nb-33Ti, Tc=9.3K, Hc= 11.0. Nb-60Ti, Tc=9.3K, Hc=12 (4.2K).Today niobium titanium alloy tube, niobium titanium alloy foil and niobium titanium alloy wire are the main superconducting magnet material used in 7 ~ 8 special magnetic fields.

The performance of niobium titanium alloy is further improved by adding tantalum ternary alloy. The performance of Nb-60Ti-4Ta is as follows: Tc=9.9K, Hc=12.4 (4.2K); The performance of Nb-70Ti-5Ta is 9.8K Tc and HC=12.8.

If you have inquiry or want to discuss your design with us, please write email to us.

We will reply your email within 24 hours.

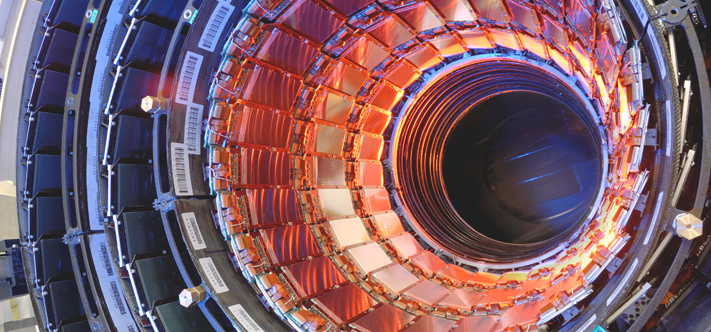

Superconducting accelerator is the first choice in the field of accelerator research and development. Superconducting accelerators have become an important part of large scientific projects such as linear collider, advanced radiation light source, free electron laser, spallation neutron source and radionuclide device. Superconducting cavity is the core component of superconducting accelerator. A superconducting cavity is an RF resonator. The superconducting cavity used in accelerators can be called the radio frequency superconducting accelerator cavity, or the superconducting cavity for short.

Niobium is an ideal metal for making superconducting accelerated resonators. Niobium can be used to make synchrotron light sources with superconducting resonators. Superconducting niobium can also be used to make free electron lasers with superconducting linear accelerators. It is used in proton accelerators and rare isotope accelerators for converting nuclear waste and producing neutrons.

Superconducting niobium plate (RRR≥300) is mainly used to make resonant cavity for RF superconducting linear accelerator, which is the core component of accelerator engineering. Most of the resonators are pressure vessels, and the forming process involves pressure forming process, which requires more performance requirements for superconducting niobium plate. In order to ensure the residual resistivity of superconducting niobium plates, carbon, hydrogen and oxygen pollution should be reduced as much as possible during processing.

The key parameter of the superconductivity of superconducting niobium bar is the RRR value (i.e. the residual resistivity of the material at 4.2K), which is generally required to be greater than 250. The higher the RRR value is, the better the superconductivity of the bar will be. The main factor affecting the superconducting properties of superconducting niobium rods in processing is the temperature rise from ingot to finished product. The faster the temperature rise is, the more serious the attenuation of RRR value is. Therefore, processing method is crucial for the production of superconducting niobium rods for superconducting accelerators. In order to ensure the residual resistivity of superconducting niobium rods, carbon, hydrogen and oxygen pollution should be reduced as much as possible during processing.

Superconducting niobium tube is often used for connecting tubes in accelerators and other devices, with different specifications and short length. In order to ensure the residual resistivity of superconducting niobium tube, carbon, hydrogen and oxygen pollution should be reduced as much as possible during processing.

High purity niobium rod is a component of multi-core superconducting composite wire.

With the development and wide application of superconducting technology, the low-temperature superconducting materials represented by NbTi and Nb3Sn have become a kind of irreplaceable high-tech materials with strategic significance and great development potential.

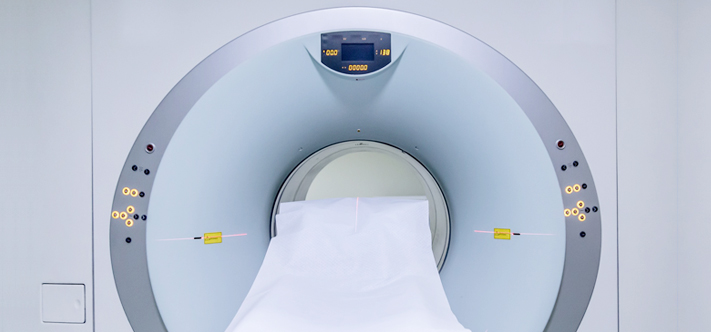

Currently it is mainly used in the following fields: ITER, Large Proton Collider (LHC), superconducting energy storage devices (SMES), superconducting high-speed train project, and in medical magnetic resonance body Imager (MRI).

The bronze method Nb3Sn superconducting wire has been used in the preparation of high field strength superconducting magnets. Because anaerobic copper has the characteristics of high conductivity and thermal conductivity, low magnetic diffusion coefficient.

In addition, it also has good mechanical strength at room temperature and low temperature. It is malleable, easy to work, and has good compound with superconductors, so oxygen-free copper is used as a stabilizer in superconducting wires.

Generally, anaerobic copper is coated outside the superconducting region. Niobium or tantalum is used as barrier material to isolate the superconducting region, so as to avoid tin diffusion pollution of copper stabilizer, which is called externally stable structure wire.

Superconducting phase transition edge detectors are often used in astronomical observation, quantum information and biological imaging.

Superconducting temperature measuring body is the core element of superconducting phase transition edge detector. Superconducting thermometers are used to absorb external radiation signals. It is composed of a superconducting thin film with a thickness of dozens of nanometers and an area of dozens to hundreds of square microns. The output signal can be measured by connecting the temperature measuring body with a lead. In this way, the output signal of the superconducting thermograph can be read.

Superconducting titanium foils can be used as superconducting thermometers. The signal lead of temperature measuring body is usually superconducting niobium foil with mature technology and stable performance.

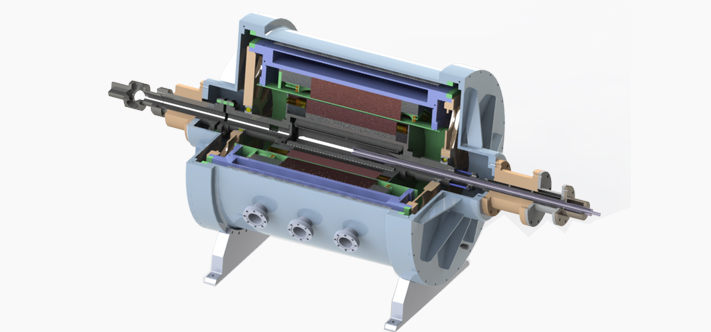

High temperature superconducting motor has the advantages of high reliability, high power density and high efficiency.

Full superconducting super efficient energy saving motor, including vacuum dewar, rotor body and stator. The winding is made of extremely fine wire niobium-titanium composite superconducting material.

The niobium titanium alloy material consists of the following components: the proportion of niobium (Nb) is 50%-55%, and the proportion of titanium (Ti) is 50%-55%.

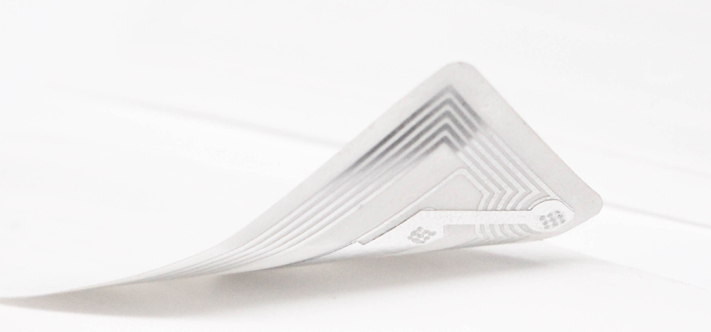

Temperature control reset module is a very important part of the electronic label: temperature sensing plate, connection column, niobium titanium alloy memory metal and pressure column are part of the module.

Niobium titanium alloy memory metal is specially made of niobium titanium alloy, which can be dented by temperature to achieve the use effect.

When the ambient temperature changes, the temperature sensing plate transmits the ambient temperature to the niobium-titanium alloy shrapnel through the connecting column. Based on the principle of thermal expansion and cold contraction, due to the material factor of niobium titanium alloy shrapnel, the shrapnel deformation occurs when the critical temperature of shrapnel is exceeded.

High precision magnetic field measurement sensor has a wide range of important applications in aerospace, national defense, military, environmental monitoring, geological exploration and medical detection.

The high precision magnetic field measuring sensor is equipped with superconducting coil. Its wire diameter is 0.1mm ~ 1mm.

The material of the superconducting coil is niobium or niobium titanium alloy, which can achieve better magnetic field compensation effect.

Niobium titanium alloy is a very important material in superconducting cable.

The superconducting magnet is divided into two parts by the superconductor niobium-titanium alloy, and the middle magnetic field is free for radiation treatment particles to pass through, so as to avoid the influence of the high-energy uniform magnetic field of nuclear magnetic resonance on the particles emitted by the linear accelerator.

Superconductor materials can effectively reduce the influence of high energy magnetic field on particles emitted by linear accelerator, and the superconducting transition temperature of niobium titanium alloy used by superconductor materials is 8-10K. In order to make superconducting magnets supercooled, the temperature needs to be reduced to about 10K, which is easy to meet the temperature requirements.

The content of Ti in alloys is generally in the range of 46% to 50% (mass fraction).

With the continuous improvement of the comprehensive performance of electronic products and the application environment, the performance of sputtering target is also put forward higher and higher requirements.

As one of the main raw materials of target material, niobium titanium alloy can make the sputtering film after sputtering to achieve a balance of high temperature resistance, corrosion resistance and other properties. These are based on niobium titanium alloys with high melting point, high conductivity, good corrosion resistance and good environmental performance.

The main applications of superconducting materials are:

1. The superconductivity of materials can be used to make magnets, which are used in motors, high-energy particle accelerators, magnetic levitation transportation, controlled thermonuclear reaction, energy storage. It can be used to produce power cables for large capacity transmission (power up to 10000MVA). And it can make communication cable and antenna. its performance is better than conventional materials.

2. Frictionless gyroscopes and bearings can be made by superconducting material.

3. Superconducting materials can be used to produce a series of precision measuring instruments, radiation detectors, microwave generators, logic components.

Add: 399 Chunhe Road, Baoshan District, Shanghai, China, 200941

Tel: +86 21 56656030

Email: info@fortu-tech.com