Fortu Tech specializes in manufacturing Nitinol (Nickel-Titanium alloy) products.

| Nitinol Regular Product | ||

| Nitinol Foil | Nitinol Wire | Nitinol Sheet |

| Nitinol Rod | Nitinol Targets | Nitinol Tube |

| Nitinol Pellet | Nitinol Fasteners | Nitinol Ingot |

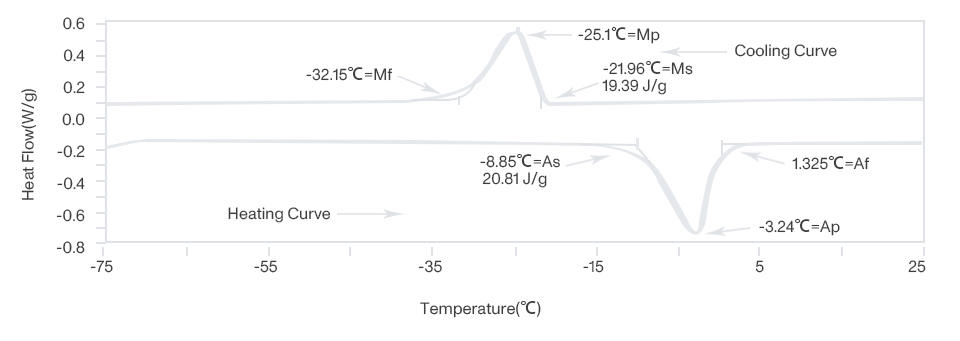

Nitinol is not only a superelastic alloy, but also a shape memory alloy. Shape memory alloy (SMA) is a metal that can remember its geometry. It automatically restores its original geometry. This remarkable property is due to a temperature-dependent martensitic transition from a less symmetrical crystal configuration to a more symmetrical one.

When Nitinol is in martensitic form, Nitinol alloy is easy to deform and ductile at lower than its transition temperature. Once deformed, the Nitinol alloy will maintain its deformed state at room temperature. Then, when the alloy is heated above the transition temperature, the alloy reverts to austenite and returns to its original shape with high resilience. As the alloy cools down, the alloy returns to a martensitic form, thus exhibiting the shape memory properties of Nitinol.

| Chemical Requirements Nitinol | ||

| Element % | Nickel | Titanium |

| Nickel-Titanium alloy | 55% | 44% |

| 56% | 45% | |

If you have inquiry or want to discuss your design with us, please write email to us.

We will reply your email within 24 hours.

| Mechanical Properties Nitinol | |||

| Ultimate Tensile Strength | Austenite | Martensite | Elongation |

| 130 KSI | 28-100 KSI | 10-20 KSI | 25-50% |

| 895 MPa | 195-690 MPa | 70-140 MPa | 25-50% |

Nitinol ingot is melted using a combination of vacuum induction melting or vacuum arc remelting. Nitinol billets are forged and hot-rolled to form an intermediate form. These intermediate forms are further made into bars, coils and sheets. ASTM F2063 is the standard that covers the chemical and metallurgical requirements for forged nickel-titanium in this form of rolling mill.

The nitinol wire is further drawn to produce a smaller diameter wire. Nitinol coils can be made into thinner sheets. The Nitinol bar is drilled with a gun to form a "hollow tube", which is then drawn into a tubular shape.

Applications for Nitinol range from consumer appliances to automotive, aerospace and medical industries.

Nitinol is used to make stents, guides, stone baskets, filters, needles, dental files, and other surgical instruments.

Nitinol assemblies are available in a variety of styles - wire, tube, sheet and foil, as well as machined or formed shapes.

Add: 399 Chunhe Road, Baoshan District, Shanghai, China, 200941

Tel: +86 21 56656030

Email: info@fortu-tech.com