Rolling is a method in which the rolled piece is pulled into the rotating rolling bar, and making cross section of the piece smaller, and the length increased.

According to the same direction of roll rotation, rolling can be divided into longitudinal rolling, transverse rolling and diagonal rolling. According to the deformation temperature of rolling deformation, rolling can be divided into cold rolling, warm rolling and hot rolling. Cold rolling is generally referred to as the process of metal rolling at a temperature where recovery and recrystallization do not occur. Because there is no hot rolling temperature drop and uneven temperature shortcomings, so thinner and more accurate strip and foil can be produced. In addition, the surface of the cold rolled sheet is bright, which can make different products with different surface roughness according to different purposes of use. Cold rolling makes the product own good performance. Cold rolling is generally used to produce sheet, strip and foil with high surface quality.

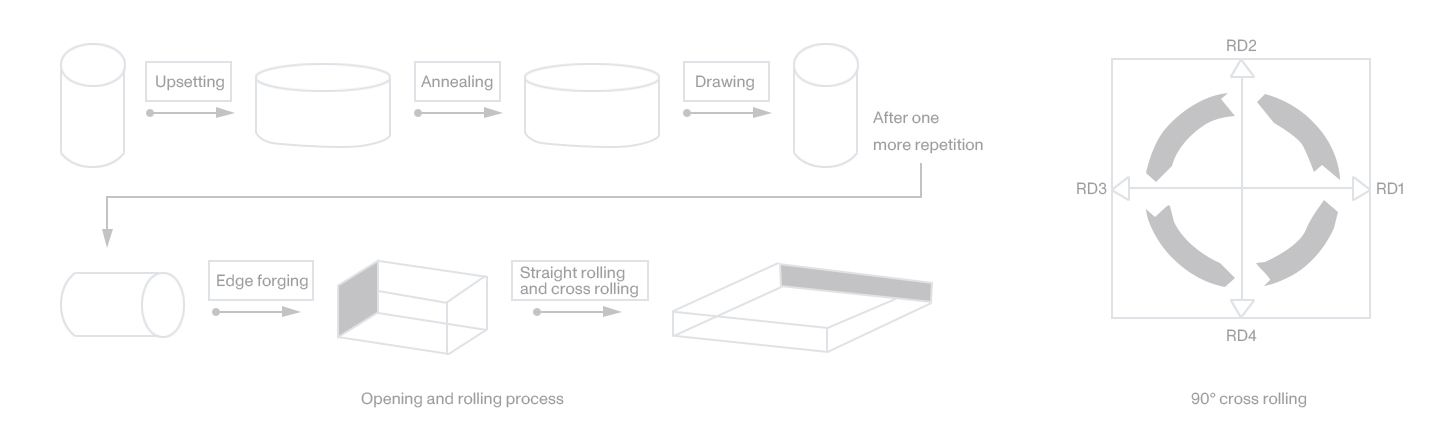

Niobium sheet, niobium strip and niobium foil are usually rolled by cold deformation. After forging and annealing, the niobium ingot is processed into thinner niobium plate and niobium strip by cold rolling. After cold rolling process, niobium products with smooth surface, precise size and excellent microstructure can be obtained.

Add: 399 Chunhe Road, Baoshan District, Shanghai, China, 200941

Tel: +86 21 56656030

Email: info@fortu-tech.com