Fortu Tech specializes in manufacturing Nb C-103 alloys (Nb-10Hf-1Ti) products.

| Nb C103 alloys / Niobium-Hafnium Alloy R04295 Regular Product | ||

| Nb C103 alloys Foil | Nb C103 alloys Wire | Nb C103 alloys Sheet |

| Nb C103 alloys Rod | Nb C103 alloys Targets | Nb C103 alloys Tube |

| Nb C103 alloys Pellet | Nb C103 alloys Fasteners | Nb C103 alloys Ingot |

| Nb C103/Niobium-base alloy containing 10 % hafnium and 1 % titanium | |||

| Shape | Standard | Type | Alloys |

| Nb-C103 Ingot | ASTM B 652 | R04295 | Niobium-Hafnium Alloy |

| Nb-C103 Bar/Rod/Wire | ASTM B 655 | R04295 | Niobium-Hafnium Alloy |

| Nb-C103 Sheet/Strip/Plate | ASTM B 654 | R04295 | Niobium-Hafnium Alloy |

| Nb-C103 Sheet/Strip/Plate | AMS 7852 | / | Niobium-Hafnium Alloy |

| Nb-C103 Bar/Rod | AMS 7857 | / | Niobium-Hafnium Alloy |

Niobium hafnium alloy C103(Nb-10Hf-1Ti-0.7Zr), (R04295) belongs to low strength series niobium alloy.

Nb C103 alloys is easy to be machined and welded. Its machinability makes sure it can be machined into various shapes.

| Annual corrosion depth of Nb C-103 Niobium-Hafnium Alloy R04295 in alkaline solution | |||

| Concentration of Sulfuric Acid Weight % | 10 | 30 | 50 |

| Annual corrosion depth (mm/year) | 0.627 | 0.247 | 0.0453 |

| ASTM Standard Chemical Requirements Nb C103 / Niobium-Hafnium Alloy R04295 | |||||||||

| Element % | Hf | Ti | C | O | N | H | Zr | W | Ta |

| Content Maximum % | 9-11 | 0.7-1.3 | 0.015 | 0.025 | 0.01 | 0.0015 | 0.7 | 0.5 | 0.5 |

If you have inquiry or want to discuss your design with us, please write email to us.

We will reply your email within 24 hours.

| Mechanical Properties of Nb C103 alloys Nb-10Hf-1Ti-0.7Zr | ||||

| Density | Melting Point | Thermal conductivity | Coefficient of thermal expansion | Working Temperature |

| 8.85g/cm3 | 2350+/-50°C | 41.9W·(m·K)-1 | 8.10(20~1205°C)/10-6K-1 | 1100~1450°C |

| The hardness of Niobium C103 alloys Nb-10Hf-1Ti | ||

| Material | Condition | Hardness |

| Nb C-103 Ingot | Casting | 154~160 |

| Nb C-103 Rod | Extruding | 152~155 |

| Nb C-103 Rod | Forging | 174~179 |

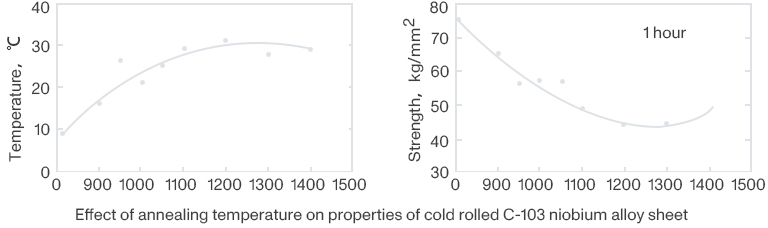

| Nb C-103 Sheet 1.0 mm thk | 1200°C,1hour annealed | 170~181 |

| Nb C-103 Sheet 1.0 mm thk | 1300°C,1hour annealed | 170~183 |

| Nb C-103 Ring | Forging | 150~169 |

Forging Nb C-103 alloys billet ---- billet sawing ---- surface processing of the billet ---- in the resistance furnace heating ---- coating oxidation protective lubricant ---- medium frequency induction furnace heating ---- upsetting forging ---- turning ---- grinding pull ---- inspection ---- heat treatment ---- die forging ---- forming ---- rolling ---- straightening ---- peeling ---- polishing ---- pickling ---- finished product annealing treatment ---- inspection

The small size Nb-C103 alloys bar billet is straightened, skinned, polished and pickled successively until the defects of ear, meat and oxidation on the surface were completely removed.

Finally, the finished product was annealed to obtain the small size high strength niobium-hafnium alloy bar.

The surface of the extruded ingot is coated with anti-oxidation protective lubricant, which can not only reduce the oxidation loss of the alloy during forging at high temperature, but also reduce the heat loss during forging.

The process of upsetting the materials several times when forging can homogenize structure in radial direction.

The first stage annealing after upsetting forging is very important, which can increase the rate of finished products.

Niobium C-103 alloys are always used in aerospace and satellite applications:

High performance radiation-cooled thrust chamber of rocket engine, nozzle extension components, nozzle parts of liquid rocket engine, jet engine’s bushings, rocket exhaust systems, assembly of ramjet engine, etc.

Add: 399 Chunhe Road, Baoshan District, Shanghai, China, 200941

Tel: +86 21 56656030

Email: info@fortu-tech.com