Fortu Tech is an ISO Certified Corporation located in China and specializes in manufacturing Pure Tantalum Wire. We have more than 20 years of pwireuction experience. Our products are Conflict Free material.

| Common specifications | ||||||||

| Thickness inch | 0.01 | 0.02 | 0.03 | 0.04 | 0.05 | 0.08 | 0.1 | 0.125 |

| Thickness mm | 0.254 | 0.508 | 0.762 | 1.016 | 1.27 | 2.032 | 2.54 | 3.175 |

The CAS Number for tantalum wire is 7440-25-7.

Tantalum wire has excellent corrosion resistance, especially in strong acids, hydrofluoric acid, sulfuric acid and other media. Tantalum has a density of 16.6 g/cm3, a melting point of about 2996°C, and a high mechanical strength and hardness.The electrical conductivity of tantalum wire is better and the coefficient of thermal expansion is lower.

Its chemical stability enables it to maintain good performance in high temperature, strong acid-base environment, and is widely used in chemistry, electronics, medical and other fields.

Tantalum alloy wire is another tantalum wire that is made of pure tantalum mixed with some elements and has special chemical properties.

| ASTM B365 R05200 Chemical Requirements Tantalum Wire | |||||||||||

| Element% | C | N | O | H | Ti | Nb | Fe | Si | W | Ni | Mo |

| Content Maximum % | 0.01 | 0.01 | 0.015 | 0.0015 | 0.01 | 0.1 | 0.01 | 0.005 | 0.05 | 0.01 | 0.02 |

| ASTM B365 R05400 Chemical Requirements Tantalum Wire | |||||||||||

| Element% | C | N | O | H | Ti | Nb | Fe | Si | W | Ni | Mo |

| Content Maximum % | 0.01 | 0.01 | 0.03 | 0.0015 | 0.01 | 0.1 | 0.01 | 0.005 | 0.05 | 0.01 | 0.02 |

| TThe specification of ASTM B365 | |

| ASTM B 365 R05200 | Unalloyed tantalum, electron-beam furnace or vacuum-arc melt, or both, tantalum wire |

| ASTM B 365 R05400 | Unalloyed tantalum, powder-metallurgy consolidation tantalum wirep |

| ASTM B 365 R05255 | Tantalum alloy, 90 % tantalum, 10 %tungsten, electron-beam furnace of vacuum-arc melt, or both, Ta10W wire |

| ASTM B 365 R05252 | Tantalum alloy, 97.5 % tantalum, 2.5 %tungsten, electron-beam furnace or vacuum-arc melt, or both, Ta2.5W wire |

| ASTM B 365 R05240 | Tantalum alloy, 60 % tantalum, 40 % niobium, electron-beam furnace or vacuum-arc melt, Ta40Nb wire |

If you have inquiry or want to discuss your design with us, please write email to us.

We will reply your email within 24 hours.

Annealed Condition (90% Minimum Recrystallized)

| Mechanical Properties of Ta Wire ASTM B365 | ||

| Diameter | Ultimate Tensile Strength | Elongation |

| 0.010" to 0.0149" | 35 000 min, psi | 10% |

| 0.254mm to 0.379mm | 241 min, Mpa | 10% |

| 0.015" to 0.0249" | 35 000 min, psi | 15% |

| 0.381mm to 0.633mm | 241 min, Mpa | 15% |

| 0.025" to 0.124" | 30 000 min, psi | 20% |

| 0.635mm to 3.14mm | 207 min, Mpa | 20% |

| Cas No. of Ta | 7440-25-7 |

| EINECS No.of Ta | 231-135-5 |

| Element class of Ta | Transition metal element |

| Relative atomic mass of Ta | 180.94788(12C = 12.0000) |

| Density of Ta | 16650kg/m3;16.654g/cm3 |

| Melting Point of Ta | 2996 ℃ |

| Boiling Point of Ta | 5425 ℃ |

| Hardness of Ta | 6.5 |

| Position of Ta | Period six, group VB, region d |

| Atomic volume of Ta | 10.90cm3/mol |

| Linear expansion coefficient of Ta 0~100℃ | 6.5×10-6 K-1 |

| Critical temperature of superconducting transition of Ta | 4.38K |

| Temperature Coefficient of Resistivity of Ta | 3820 ppm/°C |

Tantalum Wire - Premium Capacitor Electrodes & High-Tech Applications:Tantalum wire serves as a critical material in advanced electronics and industrial applications, particularly valued for its high purity, excellent conductivity, and extreme temperature resistance.

Tantalum Capacitor Applications: High-purity tantalum wire is essential for manufacturing internal capacitor electrodes in high-performance tantalum capacitors. Used in aerospace-grade electronics, medical devices, and high-frequency circuits where reliability and stability are paramount. Tantalum capacitor lead wire ensures optimal current flow in miniaturized electronic components.

Industrial & Manufacturing Uses: Tantalum alloy wire serves as durable chlorinator springs for chemical processing. Key material for Directed Energy Deposition (DED) and Electron Beam Additive Manufacturing (EBAM) in 3D printing. Tantalum wire pellets function as premium evaporation sources for: Semiconductor fabrication, Magnetic storage devices, Optical coatings, Corrosion-resistant surface treatments.

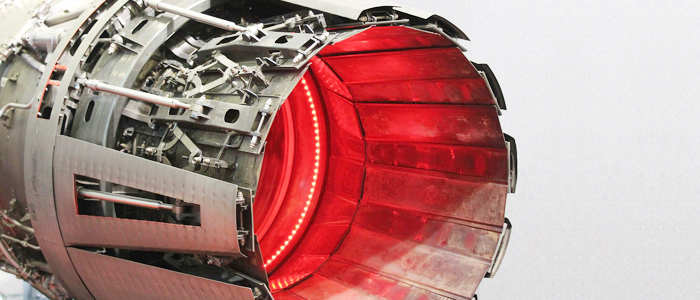

Aerospace & High-Temperature Solutions: Ideal for jet engine components and rocket propulsion systems (melting point: 2996°C). Maintains structural integrity in extreme thermal environments. Used in thermal protection systems for spacecraft.

Medical & Biocompatible Applications: Medical-grade tantalum wire offers: Complete biocompatibility (ISO 10993 certified), Non-toxic for long-term implantation, Radiopacity for enhanced imaging. Applications include: Surgical instruments, Orthopedic implants (artificial joints, bone repair), Dental reconstruction.

Specialty Components: Tantalum spring wire excels in: High-temperature environments, Corrosive chemical exposure, Radiation-intensive applications. Tantalum jewelry wire enables premium body jewelry (necklaces, earrings) with: Hypoallergenic properties, Exceptional durability, Luxurious metallic luster.

Why Choose Tantalum Wire? ASTM B365 compliant for guaranteed quality, Custom diameters (0.1mm-5.0mm) available 99.95%+ purity for critical applications Annealed or hard-drawn options.

In addition to Tantalum Wire, we also produce Tantalum Tube & Pipe, Tantalum Sheet & Plate, Tantalum Ingot, Tantalum Pellets, Tantalum Foil, Tantalum Rod&Bar,Tantalum Disc, Tantalum Shield, Tantalum Target, Tantalum machined parts, Tantalum Spherical Powder. They meet Standard ASTM B 364, ASTM B 365, ASTM B 708, ASTM B 521, ASTM F560 R05200, R05400.

Add: 399 Chunhe Road, Baoshan District, Shanghai, China, 200941

Tel: +86 21 56656030

Email: info@fortu-tech.com