Fortu Tech is an ISO Certified Corporation located in China and specializes in manufacturing Ta10W Sheet&Plate. We have more than 20 years of production experience. Our products are Conflict Free material.

| Common specifications | ||||||||

| Thickness inch | 0.15 | 0.2 | 0.25 | 0.3 | 0.35 | 0.4 | 0.45 | 0.5 |

| Thickness mm | 3.81 | 5.08 | 6.35 | 7.62 | 8.89 | 10.16 | 11.43 | 12.7 |

The tantalum-10 tungsten alloy plate inherits the extremely strong corrosion resistance of pure tantalum plates, while the addition of tungsten enhances its high-temperature oxidation resistance.

Corrosion resistance of 90%Tantalum10%Tungsten Sheet: 1. Strong hydrochloric acid, nitric acid, aqua regia 2. Organic acids (such as acetic acid, citric acid) 3. Molten alkali (such as sodium hydroxide, but be cautious at high temperatures) 4. Liquid metals (sodium, potassium).

Ta-10W alloy plate is not resistant to corrosive media: 1. Hydrofluoric acid (HF) 2. Hot concentrated sulfuric acid (>150°C).

The high-temperature oxidation resistance of Ta10W plate: 1. Above 500°C, a protective oxide layer will form on the tantalum 10 tungsten sheet, but the oxidation rate is lower than that of pure tantalum plate. 2. For long-term high-temperature use, it is recommended to operate in an inert atmosphere (such as argon) to have high-temperature oxidation resistance.

| ASTM B708 R05200 Chemical Requirements Tantalum Sheet | ||||||||||||

| Element% | C | N | O | H | Nb | Fe | Ti | W | Mo | Si | Ni | Ta |

| Ta10W alloys | 0.01 | 0.01 | 0.015 | 0.0015 | 0.1 | 0.01 | 0.01 | 9~11 | 0.02 | 0.005 | 0.01 | Balance |

If you have inquiry or want to discuss your design with us, please write email to us.

We will reply your email within 24 hours.

| Mechanical Properties of Ta10W Plate R05255 | ||

| Ultimate Tensile Strength | Yield Strength | Elongation |

| 70000 min, psi | 55000 min, psi | 20% |

| 482 min, Mpa | 379 min, Mpa | 20% |

| Machining Performance Comparison Ta-10W Sheet vs. Tantalum-12W Sheet | |||

| Processing characteristics | 90Ta-10W Sheet | 88Ta-12W Plate | Comparison |

| Hardness (HV) | 200-250 | 220-280 | The Ta12W Sheet is harder and the cutting tools wear out more quickly. |

| Cutting difficulty | Medium (requires carbide cutting tools) | Higher (requiring diamond/ CBN tools) | The Ta-12W Plate is more difficult to machine. |

| Surface finish | Better (Ra 0.8 - 1.6 μm) | General (Ra 1.6 - 3.2 μm) | The Ta12%W Sheet is prone to generating burrs. |

| Cutting parameters | Low speed, high feed rate | Ultra-low speed, small cutting depth | The Ta12W Plate requires more careful processing. |

Ta-10W Sheet: Suitable for conventional CNC machining. It is recommended to use carbide cutting tools. The coolant should be oil-based.

Ta-12W Sheet: Requires a highly rigid machine tool and diamond cutting tools to prevent cracks in the heat-affected zone.

| The physical properties of 90%Ta10%W plate | ||

| Density | 16.8 g/cm3 | High density, lying between pure tantalum and pure tungsten |

| Melting Point | 3020°C | Better than pure tantalum, suitable for extremely high-temperature environments |

| Coefficient of thermal expansion | 6.5×10-6 /K | 20 - 1000°C, excellent dimensional stability at high temperatures |

| Thermal conductivity | 54 W/(m·K) | Excellent heat dissipation performance |

Due to the high hardness of Ta10W alloy plates, special processing techniques are required: 1. Tantalum10%tungsten alloy sheets are prepared through powder metallurgy or arc melting. 2. The subsequent processing of 90Ta10W plates involves hot rolling and cold rolling, which is quite challenging. 3. 90%Ta10%W plates can be welded using electron beam welding (EBW), with the advantage of high precision and suitability for precision components. 4. Tantalum-10 tungsten plates can be welded using argon arc welding (TIG), but it is necessary to strictly protect the atmosphere (to prevent oxidation).

Processing suggestion: Before processing the tantalum 10 tungsten plate, it needs to undergo annealing treatment to reduce its hardness and enhance its plasticity.

1. Thickness of 90Ta10W plate: Commonly 0.5 - 20mm (ultra-thin sheets are used for electronic components, while thick sheets are used for structural parts).

2. Surface condition: Polished surface (Ra < 0.8 μm): Used for semiconductor equipment. Acid washed surface: Enhances the corrosion resistance of chemical equipment.

3. Certification standards: ASTM B708 R05255, GB/T 3629.

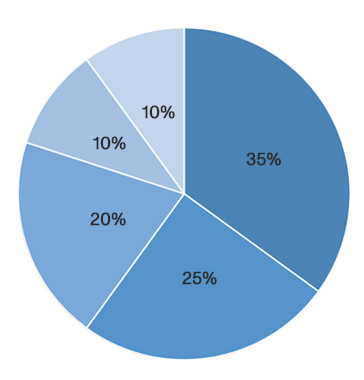

| The main application sector share of Ta-10W sheets | |

| Semiconductor equipment | 35% |

| Chemical process corrosion prevention | 25% |

| Aerospace and Aviation | 20% |

| Medical implantation | 10% |

| Other | 10% |

Tantalum-10 tungsten sheets, with their extremely high melting point (3020°C), outstanding corrosion resistance and high-temperature strength, have become key materials in extreme environments. Ta10W alloys sheets are often used in the following industries: high-temperature chemical equipment, aerospace propulsion systems, key components in the nuclear industry, high-end medical implants, semiconductor manufacturing equipment, military and defense fields, and special energy equipment.

1. In high-temperature chemical equipment, tantalum tungsten alloy sheets are used in concentrated acid reactors to resist corrosion from hydrochloric acid, nitric acid, and aqua regia. The heat exchange pipe that operates stably in acidic media ranging from 200 to 400°C. It is used as a component of evaporators for concentrating strong corrosive solutions such as sulfuric acid and phosphoric acid. The advantage of 90Ta10W plates is that they hardly react with non-oxidizing acids and maintain mechanical strength at high temperatures.

2. In aerospace propulsion systems, Ta10W sheets are used to withstand the 3000°C high-temperature gas impact on the rocket engine nozzle lining. The tantalum-10 tungsten plates are employed as a thermal protection material for components of scramjet engines during high Mach number flights. The Ta-10W sheets are also utilized in satellite thrust chambers due to their resistance to liquid propellant corrosion. The advantages of the tantalum-10 tungsten sheets include a higher melting point than nickel-based superalloys, a low thermal expansion coefficient, and excellent thermal shock resistance.

3. Among the key components of the nuclear industry, 90%tantalum, 10% tungsten sheets are fabricated into the cladding of nuclear fuel rods, which are used to prevent the reaction between nuclear fuel and coolant. Due to its resistance to the corrosion of high-temperature molten fluorine-based salts, it is used as structural material in molten salt reactors. When used as containers for radioactive waste, the tantalum-10 tungsten plates can also effectively prevent radiation leakage for a long time. The advantages of the tantalum-10 tungsten plates include a low neutron absorption cross-section (which does not affect nuclear reactions) and superior radiation resistance performance compared to zirconium alloys.

4. In high-end medical implants, tantalum-10 tungsten plates are processed into radiation therapy equipment, used as collimators and shielding covers for cancer radiotherapy. Ta-10W plates can also be processed into orthopedic implants, such as tantalum-10 tungsten joint screws and tantalum-10 tungsten bone plates. The advantages of tantalum-10 tungsten plates are excellent biocompatibility (no rejection from human tissues) and no magnetism, which does not affect MRI examinations.

5. In semiconductor manufacturing equipment, the tantalum-10 tungsten plate has the property of resisting the corrosion of high-temperature halogen gases and is processed into the cavity of CVD (chemical vapor deposition) equipment. The tantalum-10 tungsten plate is also processed into components for ion implantation machines to resist plasma erosion. Since wafer etching is carried out in an HF acid environment for a long time, 90%tantalum10%tungsten plates are processed into tantalum-10 tungsten fixtures. The advantages of the Ta10W plate include its ultra-high purity (impurities < 50 ppm) and its non-pollution of the wafer manufacturing process.

6. In the military and defense fields, tantalum-10 tungsten plates are processed into core materials for armor-piercing bullets due to their high density (16.8g/cm³), which enhances penetration power. Tantalum-10 tungsten plates can also be manufactured into missile guidance head covers (resistant to high-speed airflow ablation) and submarine pressure hull coatings (resistant to seawater corrosion). The strength advantage of tantalum-10 tungsten sheets is twice that of pure tantalum (excellent impact resistance) and it is an ideal material for stealth weapons (low radar reflectivity).

7. In special energy equipment, tantalum-10 tungsten sheets are used in the molten lithium/sodium cooling pipes of the fourth-generation nuclear reactors. These 90%tantalum-10% tungsten sheets are employed to manufacture corrosion-resistant components for geothermal power generation that are resistant to hydrogen sulfide and chloride corrosion. They are also used to fabricate the first wall of fusion experimental devices that can withstand plasma bombardment. The advantage of Ta10W sheets is that their stability in liquid metals is much higher than that of stainless steel and they are resistant to irradiation swelling (the deformation rate after neutron irradiation is less than 1%).

In addition to Tantalum alloys Ta-10W Sheet & Plate we also produce Tantalum alloys Ta-10W Wire, Tantalum alloys Ta-10W Ingot, Tantalum alloys Ta-10W Pellets, Tantalum alloys Ta-10W Strip, Tantalum alloys Ta-10W Rod, Tantalum alloys Ta-10W Tube and Pipe, Tantalum alloys Ta-10W Disc, Tantalum alloys Ta-10W Shield, Tantalum alloys Ta-10W Target, Tantalum alloys Ta-10W machined parts, Tantalum alloys Ta-10W Additive.

Add: 399 Chunhe Road, Baoshan District, Shanghai, China, 200941

Tel: +86 21 56656030

Email: info@fortu-tech.com